This is a color blindness test. Though these pictures can tell you if you suffer from color blindness, it should not replace an actual diagnosis by purchasing the real Ishihara Color Blindness Test which consists of several plates that diagnose various forms of color blindness.

If you would like to skip my story and go right to the color blindness test, you can here.

I work in the offset printing industry and purchased these plates to diagnose a pressman to see if he was able to perceive color well.

At first, I took it upon myself to teach him some the basics of ink and water balance. Before long though, I discovered a hurdle that even he wasn't aware of. One that would stop him dead in his tracks in the printing industry. He was color blind.

Color blindness doesn't necessarily mean only seeing black and white. I don't profess to know all different types, but there are some that are more subtle to discover than others. Here are some different types:

I'll now go back to the example in the beginning. It was just a matter of time before someone like this came along. I have worked with a few women before in the press room, but by and large most were men. If ten percent of all those who have come through have a color deficiency, then sooner or later it was bound to happen. The lesson: I had better be more preemptive.

So needless to say, all who enter my press room, must take the Ishihara Color Blindness Test. It is simple to give and saves a lot of investment from the employer side as well as employee. There are other tests that can be purchased for around $800, but I highly recommend purchasing the Ishihara plates for this purpose.

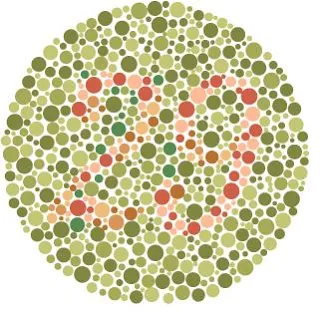

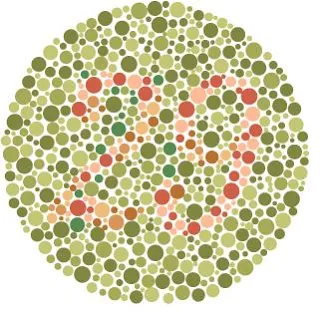

However, here is a simple test online that will help you. It is not meant as a diagnostic test, but can serve as a quick reference. Proper diagnosis should be done by a professional. Here goes.

Answers: 10 and 7

Answer: On the left hand side the proper answer is 29. If you see a 70, you likely have a color deficiency. On the right is a 57. If you see a 35, this also may reveal a color deficiency.

If you would like to skip my story and go right to the color blindness test, you can here.

I work in the offset printing industry and purchased these plates to diagnose a pressman to see if he was able to perceive color well.

At first, I took it upon myself to teach him some the basics of ink and water balance. Before long though, I discovered a hurdle that even he wasn't aware of. One that would stop him dead in his tracks in the printing industry. He was color blind.

Color blindness doesn't necessarily mean only seeing black and white. I don't profess to know all different types, but there are some that are more subtle to discover than others. Here are some different types:

- Monochromacy - total color blindness

- Dichromacy - one of the three basic color mechanisms is malfunctioning

- Anomalous Trichromacy - when colors are seen, but matched differently by the brain

I'll now go back to the example in the beginning. It was just a matter of time before someone like this came along. I have worked with a few women before in the press room, but by and large most were men. If ten percent of all those who have come through have a color deficiency, then sooner or later it was bound to happen. The lesson: I had better be more preemptive.

So needless to say, all who enter my press room, must take the Ishihara Color Blindness Test. It is simple to give and saves a lot of investment from the employer side as well as employee. There are other tests that can be purchased for around $800, but I highly recommend purchasing the Ishihara plates for this purpose.

However, here is a simple test online that will help you. It is not meant as a diagnostic test, but can serve as a quick reference. Proper diagnosis should be done by a professional. Here goes.

Answers: 2 and 5

Answers: 6 and 16

Answers: 10 and 7

Answer: On the left hand side the proper answer is 29. If you see a 70, you likely have a color deficiency. On the right is a 57. If you see a 35, this also may reveal a color deficiency.

I recommend purchasing these pictures as plates or in a book for reference.

So my advice is this: make sure anyone in your press room has perfect color perception. If they don't, there's little future for them. Save yourself and the pressman the time by doing the test right from the start. You can buy the Ishihara's Test for Colour-Blindness (concise edition) test and keep it handy to test new employees. This way you will know if they have a future.

test and keep it handy to test new employees. This way you will know if they have a future.

Additionally, you can take another color blindness test similar to this one.

So my advice is this: make sure anyone in your press room has perfect color perception. If they don't, there's little future for them. Save yourself and the pressman the time by doing the test right from the start. You can buy the Ishihara's Test for Colour-Blindness (concise edition)

Additionally, you can take another color blindness test similar to this one.

All pre-press people should undergo a colour blindness test, as well as the sales team....

ReplyDeleteTHXX

ReplyDeleteat the last 2 i can see both, the right numbers and the wrong numbers :)

ReplyDeleteVertis gives you that test when you interview with them. At least they did with me.

ReplyDeleteI ran presses for 8 years knowing I was badly colorblind the entire time. My employers never caught on. If a pressman is very careful they can fake it pretty well but definitely not perfectly. If I'd been given these tests I'd have failed miserably. Of all of those plates I see only the 16. :) Now that I'm older I probably wouldn't feel comfortable taking a job running presses even though I absolutely loved that job.

ReplyDelete16 also. Can't see the difference in some two color diode indicator lights.

Deletei dont work as a pressman now. Very happy about that !

ReplyDeleteAccording to this, I am not colourblind!

ReplyDeleteThe color blindness test is used for many people.

ReplyDeletewhere i work the prospective employee isn't required to pass any type of test except a drug test.I never quite understood their thinking here.

ReplyDeleteI work with color grading films. It's my secret that I'm color blind. I have developed other ways of telling if I'm on the right track. I've surrounded myself with instruments. I've learned what values to look for. I could only make out no 16. Is there a way to move the green spectrum down on a screen? Adobe has a new function for Deuteranomaly. Maybe it only works the other way? For normal people to see it my way? Is there a way to alter the screen to help my seeing?

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThe 16 is actually a trick. No known form of colour deficiency can cause you to fail to see the 16, even those with zero colour perception can discern it by brightness alone. It is included in the standard test specifically to catch fakers, trying to dodge military duty by falsely claiming visual impairment.

ReplyDeleteI see only the 16. My job as a physics professor has included teaching the electronics color code. I tell my students to compare the resistor to the chart carefully but I cannot help them. I also tell them to use the multimeter to verify the color code. Many of my students are planning to become doctors and I use the lab to explain what color blindness is and is not.

ReplyDeleteI'm curious,,,,I've worked as a lead operator in the business for over 30 years, all the while not knowing that I was color blind until 5 years ago.

ReplyDeleteI have never liked this business, and even with full knowledge of my deficiency, my family has always pressured me to remain in the business. My spoilage/customer rejection rate was miniscule before I had the knowledge, and it is near non-existent since I gained the knowledge. I have always used both my tools and my eyes, and if I see a proof that has a build that I suspect is in my weak spot, I will not hesitate to read into my X Rite a DE reading for that build to use as a reference for the printed sheet.

I would LOVE to get off of a press and either into the CSR or the supply side of the business, but no one will hear of it. When I plainly tell them of my deficiency, the response that I ALWAYS get is something like this, "It's never been a problem before. I need you on a press."

What would -you- do with a person with my experience and circumstance? If I had been printing along for 30+ years without incident, and one day you drop an Ishihara on me and I fail it, would you move me along out the door?

Nope, you get a pass on what the FAA calls a SODA - Statement Of Demonstrated Ability. It doesn't matter exactly HOW you came by that ability, only that you have it. They do the same thing for color-blind pilots who can correctly interpret colored guide lights and warning lights, even if they fail lab tests.

Deleteprinting is much more than doing colour having mechanical aptitude also helps with production and that's what it is mainly about these days getting the tonnes out the door

DeleteI struggled with some of them. I've been running presses for 35 years to a competent level. I did a colour blind test at work last week and got 4 out of 8!

ReplyDeleteI got 14 plates out of 17 plates for this Ishihara test but I Scored 2 where 0 is the perfect score where my score is equivalent to superior color discrimination, this test is Color Munsel Test.

ReplyDelete