Ink and water can and do mix to balance properly. But why does it work? Read on.

Conventional ink and water balance concepts of lithography make the observation that ink and water are delivered to the plate by two different delivery systems, based on the supposition that ink and water do not mix. It wasn't too long ago that ink train dampening was viewed with horror by the experts in the industry. These experts insisted that direct to the plate dampener was the only proper dampening system.

A Proven Concept

|

| Ink and water can and do mix. |

All Areas Get the Same Amount of Ink and Water

|

| All areas of the plate get the same amount of water. |

Real Examples Give The Proof

Let me digress to relate three personal experiences. First: In one of my earlier assignments, I was assigned to find web offset improvements at R.R. Donnelley. In response to the request of many pressmen, I installed a spray dampener system with total zone control. The pressmen all felt that zone control was the key to higher quality. After the system was installed, I plotted the dial settings for each spray nozzle for job after job. I was astounded to find that the settings never changed. One water input rate did fit all. Why?

A second bit of evidence - I was running quality evaluations for Goss. At the Army Times, they had two metro presses. One had direct to plate dampening and one had ink train dampening. They both ran the same job. In critical examinations by many we found no quality differences in the two products. The purists would no doubt have predicted a very serious advantage for the direct dampener. The results showed otherwise. How the water gets started into the system is not a factor.

So, when we deliver water equally across the plate, if there are inked areas that do not accept water, where does that water go? The ink accepts it, which means that the water pick-up rate of ink is a critical factor in offset printing performance.

A third example of supporting information: Recently an Australian pressman reported that he solved a very serious problem of evaporation by drying up on the roller ends by changing to a high water pick up ink. He found that high water pick up ink brought the extra water that he needed to the roller ends. He solved a water deficiency problem by changing his ink. This is a case of where craftsmanship supports science.

Therefore if ink controls the water, the key question is what do we need to know about the ink?

The Science Behind Ink and Water Balancing

|

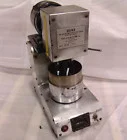

| Water pickup tester for ink. |

So plates cannot select water from the roller based on whether it has image or non-image areas. We force water onto all areas of the plate when printing. Ink must absorb the excess water. Inks therefore are the most critical factor of the lithographic process.

Questions To Consider

The practical question here is, "What can the printer do with this knowledge." Logical questions can be asked. For instance, why do we need water stops in some areas? Why do our presses roller trains tend to dry up on the ends and have excess water in the centers? More importantly, why are we constantly fighting ink and water balance?

What Are We Trying To Control?

Basically, our problem is that much of our efforts have been to control the water rather than the ink. We make assumptions that our ink is right and that water is the culprit. Press rooms are constantly changing fountain solutions and dampeners in the hunt for a good ink and water balance window. Why all of this testing and changing when the problem may be more ink related than water related?

The answer may be in how we buy our ink. Most printers buy ink by the ton with the contract going to the lowest bidder. Ink composition is like shoe composition. You get what you pay for. When cost reductions are made, commensurate quality reductions are part of the package. There's the problem! The press room is at the mercy of the budget and the price is paid on the press.

One of the most basic problems is that there are no standard ink specifications that can be followed or enforced by most printers. Most of the major printers and newspaper publishers have raw material testing capabilities. The requirements (instrumentation) are not very expensive or difficult to use. You must give your ink specification and ink evaluation the attention it requires. Otherwise, you will be working toward a two dimensional problem from only one (and possibly the wrong) direction.

by Frank Drazan

While there is a lot of validity to this, the plate CAN accept different amounts of water between image area and non image area. While some excess water may make its way into the ink train, on certain if not all dampening systems, through a squeegee effect the excess water is returned to the water reservoir as the water rollers pass the cylinder gap, perfect example to this is the principle of the Kompac water system. Something to consider...

ReplyDelete