Troubleshooting a damaged core concerns mostly web offset printing presses. It is considered a serious defect only if it prevents the paper roll being loaded onto the press. Some damage is so bad that the entire roll is unusable.

A damaged core can have several causes:

1. The shaft was improperly inserted into the roll, causing it to slip. If there is not enough grip from the shaft, it will slip and grind up the shaft (see below). This is generally the fault of the offset printer.

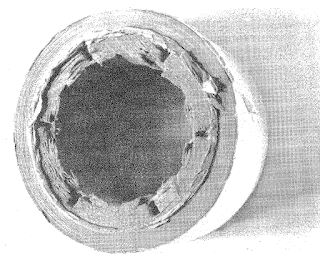

|

| Core is ground up inside because of shaft. |

2. The poor design of the shaft causes damaged to the edges (see below). Some roll stands clasp onto the ends of the roll and do damage to the core. If a roll is reloaded several times, it can get damaged to the point that there is nothing left to grip. Once again, this is the fault of the equipment and not the paper mill.

|

| Damage caused by poorly designed shaft. |

3. Poor mechanical strength of the core. This is an issue at the paper mill. At times the core cannot withstand the tension of the roll. Or it may not be able to handle the shafts that are inserted in them. This should be communicated to the paper mill in order to correct this.

|

| Poor mechanical strength of core. |

Comments

Post a Comment