Having properly set ink keys is critical to having any kind of control on your printing press. Here I would like to outline some of the principles to do this properly.

How you go about this depends a lot on the type of ink blade in your ink fountain. Some ink fountains have segmented blades while others do not.

Have the right tools

Here is an essential tool for this process. It is called a "wet film thickness gauge". It will cost around $100 but is worth it. Here is the one that we use and it works well. But a warning: once it is dropped, it is no good. So do not get a used one. If you have dropped it, throw it out and get a new one. The calibration is so precise that impacts affect it's setting.

|

| A wet film thickness gauge for ink fountain calibration. |

A word of caution.

- To zero the ink keys, you must make sure the setting is not actually at zero. If the ink fountain blade is scraping against the metal ink fountain roller, this will cause damage and you may never get it set properly. In this case, the blade must be changed. The recommended thickness is 10μm.

- Do not use the cheaper, more common thickness gauges. The picture below shows the one you should not use. They don't work in this application. You need something that will roll with the ink fountain roller.

Steps to setting ink keys to zero:

1. Set all keys to electronic zero at the control console (If your ink fountain is not controlled form a console, skip to step 3).2. Disengage the motors of the ink fountain so that the keys can be moved manually.3. Open all ink adjusting screws wide.4. Starting from the center, bring each key to a 10μm thickness using the wet film thickness gauge.5. On non-segmented blades, each adjustment can effect other areas of the ink fountain blade. Continually re-check adjustments as you move to the outer edge of the fountain.6. When all keys have a 10μm thickness, re-connect all ink key motors if applicable.7. Test all motors are engaged and functioning properly.

As part of maintenance

I recommend setting ink keys to zero every 6 months. If you just cant get the ink fountain blade to give a somewhat consistent zero across the blade then I suggest replacing it. Yes, it's a big job.

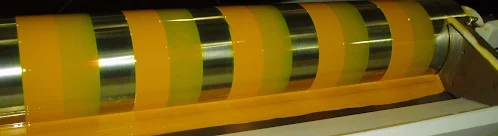

|

| Replacement ink fountain blade. |

These principles apply to any press, whether it be Man Roland, Goss, AB Dick, or any other offset printing press. If I missed anything, please leave me a comment below. Thanks for reading.

this is great information.

ReplyDeleteDo you have a ROUGH idea of what the ink film thickness should be on the form rollers

Very interesting.

ReplyDeleteDo you have a ballpark figure for ink film thickness on the form rollers that is an indicator that you are ready to print when starting up