A slime hole occurs early on in the paper making process when bacteria forms a slimy substance . White water (water that has 4% paper fibers) is then poured over a wire mesh which catches the fibers. The bacterial slime then deposits on to a wire and a hole in the paper develops.

Where do slime holes form?

In the paper making process, a wire mesh, or a fourdrinier table receives diluted water and paper. At this point the mixture is extremely diluted, only 4% pulp and 96% water. See the video of a fourdrinier table below.

Water is poured onto this table and occasionally a slimy bacterial droplet can form. The paper fibers will not settle properly and the outline of a hole, or actual hole will form. This hole makes it's way through the paper machine and dries. The bacteria then die which leaves an opening with hard crusty edges. Sometimes it will break, other times it will make it through.

|

| Photos of slime hole forming in paper machine. |

Where a slime hole is discovered.

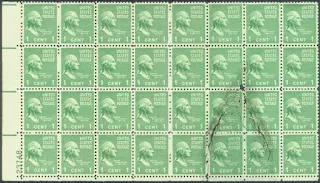

If the slime hole makes it through, it will then be wound in a roll or make it's way into a sheet pile. Hence this paper defect effects web and sheetfed offset printers. This defect can also make it's way through an offset printing press without causing any problems. The printed copy can even make it into circulation.

|

| Stamps sent to circulation with slime hole. |

This paper defect is difficult to troubleshoot because it usually cannot be spotted before it goes through the offset printing press. A break or a wrap around the blanket might occur. At this point you need to find the evidence before you can receive compensation from the paper company.

Comments

Post a Comment